自循环通风净化一体机:

Self circulation ventilation and purification all-in-one machine

整体治理法Wholeworkshop treatment

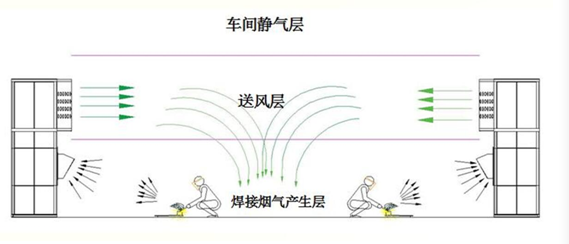

采用分层送风技术,治理效果好,不受工件设备大小尺寸影响,整个广房环境能够得到有效改善。

With layering wind-delivering technology, good effective purification, not affected by sizes of the work pieces . The entire plant environment can be effectively improved.

通风净化主机对焊烟进行治理的方式是:经过高效率滤筒净化的空气大扭从设备的顶部送下来和设备底部的两个吸气口形成一个上送下回的传统空调分层送风的气流组织方式,这种送风方式特别适合干大工件焊接烟尘治理。优势在干没有任何的管道, 主机位五可根据现场灵活选择,在夏季和冬季可以大大减少冷暖成本的支出。

The way of lhe main engine of ventilation and purificalion treals lhe welding fume is like lhis: being efficienlly purified air is coming lhrough lhe lop of the device lo meel with lwo air suction ports al the bottom which helps lo form an upper supply and bollom relurn mode like traditional air-condilioning layered air supplying. The very air supplying way is especially fil for lrealing welding fume ol large workpieces. The advantage of this device is that lhe position of the main engine can be chosen flexibly on lhe spol wilhoul any pipelines. and lhe cooling-and-heating spending cosl is also effeclively reduced in summer and winter.

有效地气流组织,每个30000m3/h的主机一般可覆盖300-400m2

Effective air distribution. Each main engine with the quantity of flow 30000m3/h could cover 300-400m2

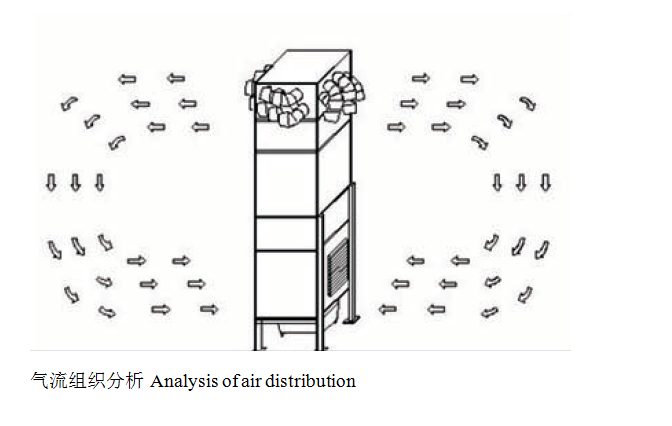

气流组织分析 Analysis of air distribution

通风净化主机在除尘器入口,设有火花捕捉金属网,有效防止火星对除尘器滤筒的损害。该除尘器风机适合长时间连续工作。且除尘器滤筒多,过滤面积大,适合入口焊接烟尘较大的场合。

Sparks capture metal nets set al the deduster's inlet of the main engine to prevent the filter cartridge being damaged by sparks. This dedusling fan can work continuously with a long time. with lots of filter cartridges which can filter largely, and it is commonly used at the situation with a large scale inlet welding fume.

Self circulation ventilation and purification all-in-one machine

整体治理法Wholeworkshop treatment

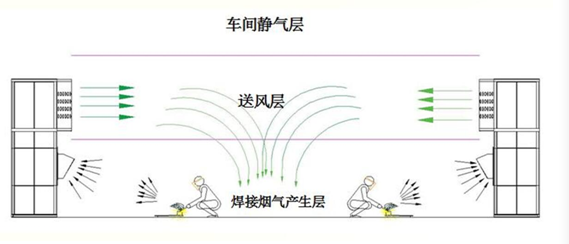

采用分层送风技术,治理效果好,不受工件设备大小尺寸影响,整个广房环境能够得到有效改善。

With layering wind-delivering technology, good effective purification, not affected by sizes of the work pieces . The entire plant environment can be effectively improved.

通风净化主机对焊烟进行治理的方式是:经过高效率滤筒净化的空气大扭从设备的顶部送下来和设备底部的两个吸气口形成一个上送下回的传统空调分层送风的气流组织方式,这种送风方式特别适合干大工件焊接烟尘治理。优势在干没有任何的管道, 主机位五可根据现场灵活选择,在夏季和冬季可以大大减少冷暖成本的支出。

The way of lhe main engine of ventilation and purificalion treals lhe welding fume is like lhis: being efficienlly purified air is coming lhrough lhe lop of the device lo meel with lwo air suction ports al the bottom which helps lo form an upper supply and bollom relurn mode like traditional air-condilioning layered air supplying. The very air supplying way is especially fil for lrealing welding fume ol large workpieces. The advantage of this device is that lhe position of the main engine can be chosen flexibly on lhe spol wilhoul any pipelines. and lhe cooling-and-heating spending cosl is also effeclively reduced in summer and winter.

有效地气流组织,每个30000m3/h的主机一般可覆盖300-400m2

Effective air distribution. Each main engine with the quantity of flow 30000m3/h could cover 300-400m2

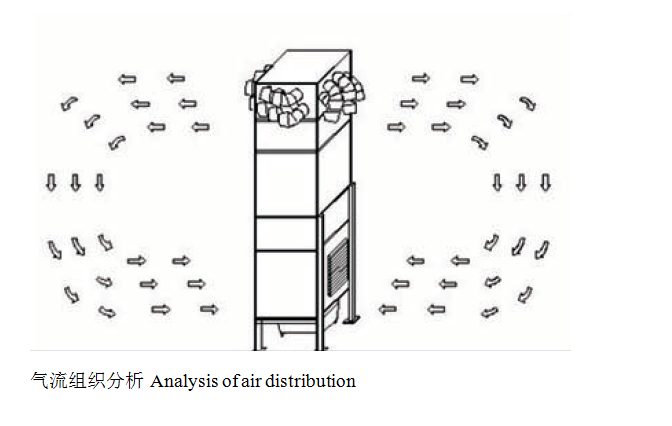

气流组织分析 Analysis of air distribution

通风净化主机在除尘器入口,设有火花捕捉金属网,有效防止火星对除尘器滤筒的损害。该除尘器风机适合长时间连续工作。且除尘器滤筒多,过滤面积大,适合入口焊接烟尘较大的场合。

Sparks capture metal nets set al the deduster's inlet of the main engine to prevent the filter cartridge being damaged by sparks. This dedusling fan can work continuously with a long time. with lots of filter cartridges which can filter largely, and it is commonly used at the situation with a large scale inlet welding fume.

联系

咨询热线:4001886698

座机:0532-837214580532-809626300532-68894059

传真:0532-66013539

Email:lanshb@126.com

地址:青岛市市北区重庆南路67号